|

| Gas Condencing Boiler |

Tuesday, 25 December 2012

Is your Boiler a Condencing Boiler

Saturday, 22 December 2012

Infinite Solar Energy Reserves

The energy of the sun can

be utilised actively or passively. With passive utilisation of solar energy,

radiation is utilised directly (e.g. windows, conservatory), in other words without

technical aids.

The energy of the sun can

be utilised actively or passively. With passive utilisation of solar energy,

radiation is utilised directly (e.g. windows, conservatory), in other words without

technical aids.Tuesday, 11 December 2012

How Biological Treatment Works

Bio-degradable organic wastes are therefore being treated by both the intermittently submerged bio-mass growing on the discs, and the suspended bio-mass present in the basin.

The rotating motion of the rotor discs create turbulence in the basin, keeping the free biomass aerated and in constant suspension until it eventually leaves with the treated effluent for secondary settling in the Clarifier (Humus Settling Tank).

Full oxygen absorption is immediately achieved due to the large contact area of the disc surfaces and the oxygen freely available in the atmosphere above the plant.

The continuous absorption of oxygen by the bio-mass allows the oxygen to penetrate effectively to the deepest parts of the bio-mass, mainly by diffusion. The immediate submersion of the rotating, oxygen saturated bio-mass causes part of the absorbed oxygen to be transferred to the suspended bio-mass in the basin. Therefore, the absorption of oxygen into the process is not through direct absorption of air by the wastewater, but rather almost exclusively through the absorption of oxygen on the wet surfaces of the bio-mass growing on the disc.

The oxygen absorption is so effective that despite the fact the oxygen is absorbed by both the disc bio-mass growth and by those suspended in the basin, over 2mg/L of oxygen is still present in the liquid leaving the Rotating Disc stage.

Since the waste substances present in the liquid are constantly converted into harmless substances, all bio-mass within the rotor unit is continually increasing. The excess bio-mass is automatically removed from the Rotating Disc stage by the flow of the wastewater through the plant.

Thursday, 22 November 2012

Saturday, 17 November 2012

Boiler Ready Exhaust Solutions

The quality exhaust systems you need, provided with speed and accuracy

Cleaver-Brooks

installation-ready boiler exhaust systems are more than the sum of their

interchangeable male and female parts. They are complete solutions that provide

the latest technology to enhance the performance of your boiler. Our CBI

insulated exhaust systems are perfect for venting gases from liquid, oil, or

solid fuel-fire boilers. Ranging from 6 to 48 inches in diameter, they are

ideal for industrial and commercial applications.

Cleaver-Brooks

installation-ready boiler exhaust systems are more than the sum of their

interchangeable male and female parts. They are complete solutions that provide

the latest technology to enhance the performance of your boiler. Our CBI

insulated exhaust systems are perfect for venting gases from liquid, oil, or

solid fuel-fire boilers. Ranging from 6 to 48 inches in diameter, they are

ideal for industrial and commercial applications.Wednesday, 14 November 2012

Next-generation condensing tankless technology is here.

It simplifies tankless and offers a better hot water experience.

Navien Condensing Technology: Efficient, sustainable and easy for you.

Thursday, 8 November 2012

Going green with grey water

![clip_image003[7] clip_image003[7]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEjSXaTV_IdiPGbR_6dyE0dT1UFbZ4_NT3_t-UrOjYzxjDMyPnqOPbNOKf8KXl_QOcguSE3-Fdd-5tP3dTesqyXBZ8CkWlMkljpJfKiyZKaFy2cwFrLHiDSh0KnffAayV7Jje9P9BGLfCola/?imgmax=800)

Greywater is wastewater from showers, baths, wash basins, washing machines and kitchen sinks although for recycling purposes kitchen sink and washing machine water is normally excluded because it is too greasy and/or contains too many.

![clip_image005[6] clip_image005[6]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEiyoFdMwdugRq8kYcOkhuW8kIlDXFtuA97dv-IcCXwz6jYRSDVtfREZPZNs4NPNoF1Zyw4NqegcV-sx-CiXniUc4OGOgeg8CKWe4oPza-q3H3dIlNpGIRRkcxONL8p9XvCUTWxJySr8UT8H/?imgmax=800) Unlike rainwater, greywater requires filtration to remove hair, skin and soap products from the water and chemical or biological treatment prior to reuse. The potential level of human contact with the water in its end use will determine what level of treatment is required. For example greywater used for hosing down vehicles will require a high water quality because the risk of human contact with the water is greater in highly pressurised systems. There are advantages of implementing a residential greywater system in your home. is peace of mind. Peace of mind knowing that you are lessening your footprint on this planet by using less water, and reducing the amount of water being municipally treated. In an ideal world, all greywater would be either used again as in irrigation of plantings , or it would be sent to a separate treatment facility separate from blackwater. There is no need to treat greywater the same as blackwater.

Unlike rainwater, greywater requires filtration to remove hair, skin and soap products from the water and chemical or biological treatment prior to reuse. The potential level of human contact with the water in its end use will determine what level of treatment is required. For example greywater used for hosing down vehicles will require a high water quality because the risk of human contact with the water is greater in highly pressurised systems. There are advantages of implementing a residential greywater system in your home. is peace of mind. Peace of mind knowing that you are lessening your footprint on this planet by using less water, and reducing the amount of water being municipally treated. In an ideal world, all greywater would be either used again as in irrigation of plantings , or it would be sent to a separate treatment facility separate from blackwater. There is no need to treat greywater the same as blackwater. Australian-owned Nubian Water Systems recently launched the OASIS

![clip_image007[6] clip_image007[6]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEgs2tjQFczgzX_nyrYYSbXsw_Lyq7RkWsyAZdo9_M1XA1NOh9eZAQzScOUFblstu7G5PVRiavfz0lujKoDNTLTSQ20nCc1fxdAJIDj_PTVpJvLAKefuIUwP7uSucML2zAzHw5Z55eBoAVio/?imgmax=800) Domestic Greywater Treatment System (GT600), a practical and affordable urban water conservation solution generating a saving of almost 400 litres of drinking water a day for the average 4 person household. OASIS takes the greywater generated by baths, showers, laundry and hand basins and treats it to

Domestic Greywater Treatment System (GT600), a practical and affordable urban water conservation solution generating a saving of almost 400 litres of drinking water a day for the average 4 person household. OASIS takes the greywater generated by baths, showers, laundry and hand basins and treats it to A high quality suitable for garden irrigation, toilet flushing, clothes washing and car washing. The compact, above-ground design of the OASIS GT600 is ideal for urban housing. No excavations are necessary and the entire system can be up and running within 24 hours of delivery.

Wednesday, 10 October 2012

Wednesday, 19 September 2012

Are You happy in Hot kitchen ? Ventilation is impaortant for kitchens

Also when installing a kitchen ventilation solution there are many hazards that need designing around, such as fire risk, dangerous fumes and odour nuisance.

Specialists should have well Knowledge and sharpened experience about kitchen exhaust systems

Saturday, 15 September 2012

Katherm HK – decentralised air conditioning from the floor

Wednesday, 12 September 2012

Secondary Loop Chilled Water In Super High-Rise

This article presents the alternative design configurations for the secondary chilled water system in a super high-rise commercial building currently being constructed in Hong Kong. The original design configuration is evaluated and compared with an alternative design configuration concerning energy performance. Both configurations are implemented in this building to test and evaluate their operational performance.

The following article was published in ASHRAE Journal, May 2008. ©Copyright 2008 American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. It is presented for educational purposes only. This article may not be copied and/or distributed electronically or in paper form without permission of ASHRAE.

Download Article!

Tuesday, 4 September 2012

Capitoline Trans-a-plate Design Manual for Heating, Ventilation and Air Conditioning: With Coordinated Standard Details

Saturday, 25 August 2012

What is CPVC Pipe?

Chlorinated polyvinyl chloride (CPVC) is a thermoplastic pipe material. Nationally accepted since 1982, CPVC pipe has many benefits when compared with other plumbing materials. It is primarily used for supplying hot and cold potable water, and in industrial liquid applications.

CPVC pipe has become a modern standard for water supply and liquid lines because of its cost saving benefits over metal piping. It is less expensive than copper piping and materials, as well as being lighter, making it faster and easier to install, saving on labor costs. The thermal conductivity of copper pipe is 2500 times greater than CPVC pipe, meaning it provides significant energy savings while keeping water hotter longer.

CPVC pipe is immune to galvanic corrosion and resists scale build up. It is also resistant to chemicals, and durable against their residues. Being plastic, it is not subject to electrolysis, the process in which water breaks down into oxygen and hydrogen gas. Installation is safer and faster, requiring only a special solvent cement, as opposed to a torch and solder for metal piping. CPVC piping generally lasts longer, as it is less susceptible to failures.

Thursday, 23 August 2012

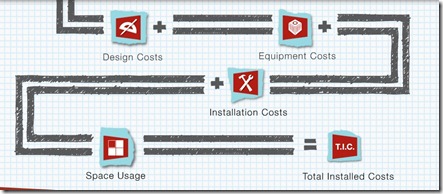

Total Installed Costs (TIC) - A More Complete Way To Compare HVAC Systems.

A truly comprehensive comparison of upfront HVAC costs includes equipment plus potential hidden costs like design costs, installation tooling, rigging, building modifications, and controls integration.

Talk to Mitsubishi Electric Cooling and Heating, America’s #1 selling brand of ductless systems, about how our solutions can save money on a TIC basis and the many advantages of Mitsubishi Electric systems – precise zoning, energy efficiency, simultaneous heating and cooling, low service requirements, and more.

Download Mitsubishi Electric's white paper on Total Installed Costs, at http://www.totalinstalledcosts.com/.

—Mitsubishi Electric

Saturday, 18 August 2012

DuctSox is a manufacturer of textile air dispersion products

DuctSox is a manufacturer of textile air dispersion products for open ceiling architecture, critical environments, and under floor applications. fabric systems are a cost effective, aesthetically attractive alternative to metal ductwork. DuctSox strives to be the leader in the industry through a commitment to quality, service, and innovation.

DuctSox products are used to distribute and disperse air in Open Ceiling Architecture. There are two products to choose from: the Internal Framework System or our Traditional products.

The Internal Framework System option is also known as SkeleCore. It is available in two different models, SkeleCore FTS and SkeleCore IHS. Both models provide aesthetic enhancement and improved performance characteristics.

Traditional DuctSox products come in either Standard or Surface Mount.

DuctSox are custom engineered and are available with several different airflow models, fabrics, and suspension systems. We also offer performance enhancement options, including the Flow Control AFD and FinalFilter, and personalization options, including company logos, text, photos, and more!

Friday, 17 August 2012

The Five Biggest Myths About Saving Energy in the Summer

This summer has already set temperature records around the nation, and we're still in the dog days of August. With money tight, and temperatures high, there's a temptation to test out unconventional ways to beat the the heat. But these odd home remedies can end up wasting energy and costing more money. Here's how to know what really works when you want to keep cool for cheap.

Myth: Cranking the thermostat lower will make the house cool faster.

Usually not. Trane and Lennox make some nice variable speed air handlers, which can adjust their output to match demand. But most homes' units have just a single fan speed—on. As such, the house's temperature will always adjust at a fairly set rate. Cranking the thermostat to 60 to take a shortcut to 70 doesn't make a difference—the hot air moves at a set rate of speed. By undercutting the desired temperature, you're simply wasting an extra 10 degrees worth of energy and money.

Myth: Turn off the A/C while you're out.

If you're out all day with the A/C off, it takes a lot of work for a central A/C system to bring a hot house down to the desired temperature. Yet it's even more wasteful to keep it running for eight hours. The answer is to invest in a programmable thermostat, which can let the house warm through the day, then gradually lowering it to the right level before you return. Adjust the temperature up 7-10 degrees F while you're away, and a programmable thermostat can still save you up to 10 percent on your annual heating bills. Reduce the demand on the system by closing curtains before you leave, to block the afternoon sun while you're gone.

Myth: Run ceiling fans to keep empty rooms cool.

Ceiling fans work by generating a wind chill effect, not by lowering a room's temperature. Essentially, they cool people, not rooms. That's not to say that fans aren't effective at lowering your cooling bills—in fact, using ceiling fans in conjunction with an A/C will allow you to comfortably raise the air conditioner's setting by several degrees. But, just like the lights, you should turn your ceiling fans off when you exit a room.

Myth: Closing vents on a central air system will boost efficiency.

This seems logical, but it can actually end up costing you a lot. Some sophisticated, super-efficient homes can effectively divide into zones of HVAC control. But most modern central air systems are balanced to distribute air throughout an entire house. So if you randomly close a register, the system keeps cooling and pumping without delivering the cool air to a usable space. You're basically paying to keep the inside of your A/C ducts frosty. The compressor/condenser can cycle too frequently, putting additional strain on the system, leading to accelerated wear and tear. And for all the damage, it's not actually saving any energy. If you have a big house and you only want to keep a single room cool, consider a ductless mini-split air conditioner, or a basic window unit.

Myth: Air conditioning is the only way to keep cool.

We have it nice in America in 2012, but ubiquitous A/C is hardly the worldwide norm. People cope. And their strategies can come in handy. When managing editor Brian Barrett's A/C went out earlier this summer—in Alabama—he and his wife and dog hunkered down in the basement, a padded layer of carpet separating them from the cool concrete floor. A caveat from Barrett: "That only works if your basement's not too creepy." Editor-in-Chief Joe Brown, on a trip to Zambia some years back, received a set of damp sheets as he checked into his evening's lodgings. "It's so hot, the water in the sheets evaporates," Brown says. "By the time you wake up, nothing is wet." And features editor Harry Sawyers, as a kid at SEC college football games and on sweltering Georgia campouts, learned to grab a piece of ice from the cooler, wrap it in a rag, and move the melting cube from wrist to wrist. "Then you just wring the melted ice water out of the rag, right down your neck. It's country, but it works."

How do you optimize your system's performance—or beat the heat without A/C? Wipe the sweat off the keyboard and let us know.

Sunday, 12 August 2012

Adaptations in Data-Center Cooling

May 1, 2012 12:00 PM, By KEVIN DUNLAP and JOHN BEAN JR., Schneider Electric, West Kingston, R.I.

A look at developments giving new life to traditional perimeter cooling systems

Despite inroads made by newer approaches to data-center cooling, such as close-coupled systems, in recent years, changes to industry standards, improved components, and the industry adoption of energy-efficient air management have allowed perimeter cooling (commonly referred to as computer-room air conditioners [CRACs] or computer-room air handlers [CRAHs]) to maintain its position as the most widely accepted choice for cooling in mission-critical information-technology (IT) environments. This article examines those developments.

Air Management

During the 2000s, as data-center heat densities rose at a seemingly exponential rate, the limitations of raised-floor air distribution and the disconnect between heat generation and heat removal became major barriers to IT cooling. This gave rise to new cooling architectures that are closely coupled or “in row” with IT loads for localized heat removal. Preventing hot- and cold-air streams from mixing increased the efficiency, capacity, and predictability of data-center cooling systems and led to the adoption of hot- and cold-aisle containment systems. While these further prevented mixing of hot- and cold-air streams, they also allowed traditional perimeter systems to isolate air streams and act in a closely coupled fashion without requiring air conditioning in close proximity to heat loads.

Similarly, perimeter cooling systems were able to overcome the efficiency gains achieved by the variable airflow of closely coupled cooling systems. The use of supply-side temperature control focused on the IT inlet and fan-speed control employing underfloor pressure sensors used in conjunction with containment strategies leveled the playing field with in-row systems. As an alternative, the deployment of pressure-regulated and fan-assisted floor tiles in perimeter cooling architectures as a means of providing variable air volume to IT equipment has become a pervasive practice in data-center design.

CRAC Components

The CRAC industry mostly has leveraged components from the commercial air-conditioning industry. While designers, manufacturers, and users of CRACs have understood the benefits of energy efficiency for several decades, they have been dependant on the larger commercial air-conditioning market for help driving demand. After a few oil crises and with increased environmental awareness, the commercial market now has substantial motivation for efficiency improvements, which has increased the number of component choices available to CRAC designers:

• Compressors. The CRAC industry long has understood the advantages of matching cooling capacity to thermal load. Initially, this was achieved with semihermetic compressors using a cylinder-unloading technique and multiple refrigeration circuits. This approach typically provided two to six steps of capacity regulation. Any of those steps matching actual load, however, was highly unlikely. Additionally, significant mechanical losses were associated with the unloaded cylinder(s).

Today, we see compressor-modulation schemes offering significant capacity turndown and almost step-free proportionality from minimum to maximum capacity. Particularly favorable is the use of variable-speed compressors. Frequently, a variable-speed compressor is combined with a constant-speed compressor on a single refrigeration circuit. This method provides high efficiency with large proportional turndown, along with lower first cost. Other choices may include pulse-width modulation of compressor pumping. This is intermittent interruption of pumping while a compressor runs continuously, which offers exceptional turndown. Regardless of the modulation technique, more closely matching cooling capacity to cooling load provides substantial efficiency gains.

• Fans. Legacy CRAC units typically used a forward-curved centrifugal fan in combination with a motor couple by belt with variable-pitch pulley. The adjustment of the variable-pitch pulley provided a limited adjustment of final fan-drive speed. This adjustment traditionally was limited to initial startup (compensating for different static pressure). Forward-curved fans were highly sensitive to reduced performance based on discharge considerations and offered modest static efficiency.

Today, we see the use of electronically commutated fans. These fans offer the ability to adjust speed in real time based on control algorithms that monitor the airflow demands of a data center. The use of backward-inclined, as opposed to forward-curved, fans has provided higher static efficiency and reduced sensitivity of fan-discharge configurations.

• Expansion valves. The combination of variable-speed fans and modulating compressors can make accurate regulation of refrigerant flow into a cooling coil difficult. Expansion-valve rangeability will be inadequate when legacy mechanical valves are used with variable-capacity compressors and fans.

Electronically controlled expansion valves can accurately regulate the flow of refrigerant into a cooling coil over the wider operating conditions introduced by airflow and compressor modulation. This wider rangeability is particularly important, as incorrect metering of refrigerant into a cooling coil can greatly reduce system efficiency and compressor reliability.

CRAC-Industry Standards

Until 2010, data centers were exempt from the requirements of ANSI/ASHRAE/IESNA Standard 90.1, Energy Standard for Buildings Except Low-Rise Residential Buildings. A common theme of the 2010 version of the standard is the need for economizer-based cooling in new data centers. Exemptions are limited, depending on ASHRAE climate zone and the base load of a data center.

Recently, the Air-Conditioning, Heating, and Refrigeration Institute (AHRI) announced an organizational meeting for a new section that would include data-center cooling products. This may open the door for third-party certification of cooling-product performance. AHRI presumably will leverage ANSI/ASHRAE Standard 127-2007, Method of Testing for Rating Computer and Data Processing Room Unitary Air Conditioners, which is being revised to include more appropriate rating conditions, based on actual return-air temperatures achieved with contemporary best practices.

Economizers

As local code agencies adopt newer standards and states pass their own requirements, the demand for economizers and the ability to leverage resulting efficiency gains increase. For many new buildings, data centers can be designed around an architecture that can leverage air-side economization. Applications such as high-rises and data-center retrofits, however, must leverage a water-side system to take advantage of economizer operation.

Water-side economizer configurations have been available for perimeter cooling systems for many years. This approach uses the heat-of-rejection water loop as a cooling fluid when the outdoor temperature is cool enough. The system diverts the cold fluid away from the condenser to a secondary free-cooling coil. Most systems have the ability to operate in partial economization with the vapor-compression system operating at part load.

A considerable number of data centers are taking advantage of perimeter units as the filtration, humidification, and control function of an air-side economizer system. Placed on an outside wall and fitted with a hot-air return duct connected to outside air, a unit can serve as a control source utilizing outside air and mechanical cooling during economizer operation. When outside air is cold enough to provide all or a portion of the cooling capacity, the unit reduces or shuts off the vapor-compression cycle to save energy and opens a damper to leverage outdoor ambient temperature. Routing this cold air through a perimeter system keeps the air entering a data center filtered and controls air moisture during economizer operation.

Perimeter-cooling economizer modes once were limited to the air-side approach described above or a water-side system utilizing a secondary coil and heat exchange with existing heat-rejection fluid. As a result, air-cooled systems did not have an economizer option. Recently, that changed, with a newer option in air-cooled systems using a secondary coil to route refrigerant to a thermal siphon circuit and a refrigerant pump to circulate the refrigerant. When outdoor temperature allows, the unit turns off the vapor-compression cycle, and the pump takes over refrigerant circulation. The use of a refrigerant pump, as opposed to a compressor, in this mode reduces energy consumption while providing the necessary cooling. This configuration expands economizer options and extends the ability of perimeter cooling to meet the needs of customers and engineers designing around new industry standards.

Summary

Just a few years ago, it appeared perimeter cooling was giving way to new data-center cooling architectures and the result would be a decline in market share. Changes in industry standards, new air-distribution methods, advances in components, and increasing economizer demands have changed what once seemed to be an inevitable fate. While most industry reporting agencies agree that row and rack cooling and air-side economizers will experience higher market-share growth rates over the next several years, perimeter cooling represents by far the largest share by cooling type and is expected to be flat or slightly up over the same period. With perimeter cooling’s considerably greater share, it will be many years before other cooling architectures catch up.

Thursday, 9 August 2012

Valve Selection Crucial in System Design

Many factors influence the selection of valves and process tubes in refrigeration and air-conditioning systems

Manufacturers and designers of air-conditioning, refrigeration, and heat-pump systems must determine the process that will be used for evacuation, charging, and run testing their systems. Valves and process tubes provide the necessary access to the system, but before implementing a solution users must consider the factors specific to each application, including ease-of-use, flow rate, leak rate, cost, and field-service requirements.

Within heating, piping, and air-conditioning applications, there are several commonly used methods for introducing air, liquids, and gas into the system. Options include the Schrader-style valve, high-flow valves, process tubing paired with connectors, and a valve quick-connection system. By understanding how each solution works and its benefits and limitations, users can make informed decisions about the option that best complements their specific requirements.

In addition to evacuating and charging air-conditioning and refrigeration systems, valves are used for evacuating and charging numerous other systems, including chillers. Additionally, valves are used in the manufacturing process of heat pumps to draw a deep vacuum on all units to pull out contaminants that would affect the quality of products.

Sleeve-activated connectors on a split system.

Schrader-style valves can be used for this purpose; however, they are subject to low flow rates, which may be problematic when efficiency is key—especially because multiple stages of evacuation may be required along a production line. Although a special connector can be used to fill and evacuate the systems directly through a straight tube and eliminate the valve restriction, the extra station for pinching and brazing at the end of an assembly line requires additional time and expense and increases the possibility of leaks. Valve quick-connection solutions solve both of these limitations, allowing high flow rates without the extra pinching and brazing requirements.

Another application example is found in the manufacturing process of split-system air-conditioning units. For charging, evacuating, pressure testing, or vacuum testing these systems, connectors can be used in the place of the Schrader on the service valve. Options such as internal lever-action connectors provide reliable connections and feature ports that allow process mediums to be introduced directly through the service valves. These connectors feature a safety design and pressure-assisted gripping collets that prevent accidental disconnects during high-pressure applications.

Proper processing selection for these and other applications relies on multiple factors, and by understanding the advantages and limitations of each valve, users can select a solution that will offer the appropriate performance capabilities while meeting the necessary cost and maintenance requirements.

Wednesday, 8 August 2012

Air/Dirt Separators Improve Distribution Efficiency

Better-quality water results in improved heat transfer

In 2006, a study of the 5,500-ton-capacity chilled-water loop at Missouri State University (MSU) in Springfield, Mo., showed the water being circulated had the consistency of molasses and included a mixture of clay, microbiological particles, and outdated glycol. Thermal conductivity was poor, resulting in inefficient distribution.

MSU installed its first Spirovent separator in 2008. Chiller-evaporator tubes that previously needed to be cleaned three times a year stayed clean for 18 months and beyond. Work orders for venting and gurgling noises in pipes have all but been eliminated.

Since the initial installation, 25 more Spirovent separators have been installed, with four more in the shop waiting to be added.

Temple Hall used to require 1,200 gpm at a 5°F delta-T. Since the addition of a Spirovent separator and pressure-independent valves, it requires 675 gpm and achieves a 14°F delta-T on a day when the outside temperature is 98°F.

Pummill Hall has 10°F-rated coils producing 14°F to 16°F delta-T, resulting in fewer pumps running.

Bob Eckels, director of facilities management for MSU, said: “The installation of a chilled-water loop at Missouri State University has transformed the delivery of cooling to our buildings. The introduction of Spirotherm dirt and air separators into this system has greatly enhanced the heat transfer, which, in turn, is creating more energy savings through reduced run time of our chillers. We are very pleased with the Spirotherm product.”

Spirotherm manufactures high-efficiency air and dirt separators for pipes up to 36 in. in size with flow rates to over 30,000 gpm for individual-building and central-plant applications. With a patented coalescing medium completely filling a vessel, air and dirt are reduced to unprecedented levels, enabling improved heat transfer, reduced maintenance, and greater distribution efficiency.

.jpg

)